Miracles Could Happen in 1 Minute! PlantStream® Is a Genius 3D CAD System That Can Design 1,000 Piping in an Instant, Even for a New User.

Behold, This Is True DX.

- Behold, This Is True DX.

- Resolving Challenges Through DX in Plant Layout Design

- Auto Routing Function, Layout of 1,000 Piping in 1 Minute

- Purely Domestic "PlantStream®".

- The Real Selling Point Is Not Speed but Accuracy

- Evolution Continues, Even Electrical & Instrumentation Cables Can Now Be Designed Automatically.

- Thoughts Behind the Sophisticated UI

- They Can Change It Because They Are Ventures.

- Contact Us, etc.

- Summary

Hello, this is the “Plant Hyakkei” Editorial Department.

The term DX (Digital Transformation) is heard everywhere.

In reality, however, I feel that the term is symbolic and people have different ways of perceiving it.

In the words of METI (the Ministry of Economy, Trade and Industry),

Companies must respond to rapid changes in the business environment and use data and digital technology to transform their products, services, and business models based on the needs of customers and society, as well as their operations, organizations, processes, and corporate culture and climate, to establish a competitive advantage.

The objective is to “establish a competitive advantage” through the use of digital technology.

However, some people may mistakenly believe that DX is merely about the adoption of information technology or the use of digital tools. The process of digitizing past analog business processes is just “Digitization”, and it doesn’t encompass the broader transformation and changes in business models that true DX refers to.

Today, I would like to introduce PlantStream Inc.

This is a venture company born in 2020 that proposes DX in the plant engineering field by developing the industry’s one and only product. What kind of new value will this company create, and how much is it going to revolutionize not only business operations but also corporate management and the industry itself?

I recently visited their office and experienced the product firsthand, and also interviewed the company about its development concept and backstory.

Let’s start with Plant Hyakkei!

Resolving Challenges Through DX in Plant Layout Design

DX in the Japanese plant industry is making slow but steady progress, including AI analysis of big data to optimize plant operation management and maintenance.

To begin with, there are two major challenges faced by the Japanese plant engineering industry.

(1) How to increase productivity to eliminate the decline in the working-age population?

(2) Assurance of quality of production to supplement skills.

The reason for using the prefix “Japan’s” is that, in recent years the technological capabilities of emerging countries such as China and India have been rapidly improving, and all of these countries have grown up with DX.

Japan has always been more advanced than other countries in plant engineering, but it’s a glory of the past.

In 2020, a company with innovative tools that broke the conventional wisdom flow suddenly appeared on the scene. The product had a strong impact not only in Japan, but also around the world, and it is only recently that the plant industry has been astonished by it…

In many cases, revolutions that always surprise people often come from fusion rather than simple updates. The years of experience and technical capabilities that plant engineering companies have built up are steadily being passed on to their successors. However, this knowledge still relies on human expertise and continues to require both mentors and successors to ensure a smooth transition. (Personally, I feel that this is diluted by the timing of each generational shift.)

If all information is systematized by using technology, both of them, as well as independent specialized departments, may not be needed and only one plant designer will be needed in the future.

I may have kept you waiting a little too long, but the company we’re going to focus on today is PlantStream Inc.

Chiyoda Corporation, a major plant engineering company in Japan, and Arent, an IT startup company, established a 50:50 joint venture.

One major plant engineering company’s extensive industry knowledge and network, combined with the advanced IT expertise and agility of IT startup, came together to create a perfect synergy. They transformed into a truly complete entity by complementing each other’s areas of expertise.

Looking back, I can’t recall a time when venture (startup) companies made such a prominent entry into this industry. While it’s true that the brand power of Chiyoda Corporation has played a significant role, there’s no doubt that even without it, this remarkable product had a profound debut that left a lasting impression on everyone in the plant industry.

Auto Routing Function, Layout of 1,000 Piping in 1 Minute

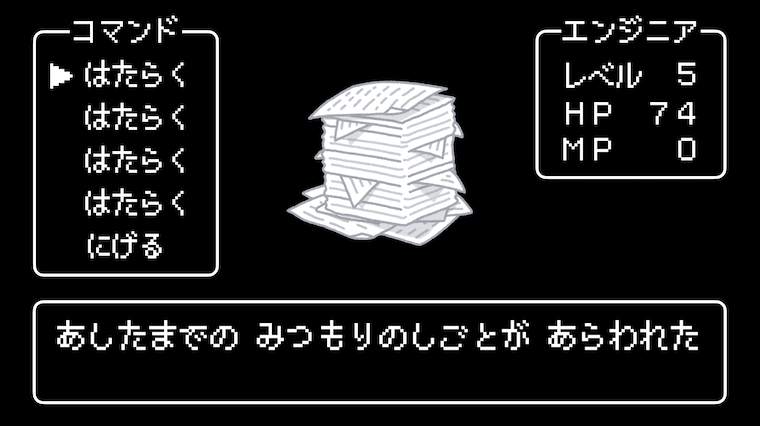

Until now, plant design using CAD has been a labor-intensive process with an accumulation of data input by engineers. Naturally, if there were any changes in specifications afterward, the design had to be re-examined from the beginning, and in some cases, a dedicated operator was required.

However, PlantStream® is equipped with an “Auto Routing Function”.

Don’t be surprised, the system automatically routes 1,000 pipes in only one minute!

Let’s take a moment to think about this, Google MAP, which we use daily, will analyze and suggest the best route to us in an instant, no matter how long the distance or how complicated the conditions are.

Furthermore, the game industry is said to be the representative industry of Japan. Game software development is created by making regular use of such computing tools. Even from the perspective of the same manufacturing industry, they are far ahead of the curve. For example, the *”RPG Maker” was created to fulfill the desire of users to create games easily without learning how to program, and even amateurs can create original RPG games easily. The first version was created in 1990, and the quality has now reached a level as good as games developed by famous game makers just a few years ago.

*RPG Maker

“RPG Tool” or “RPG Maker” is a series of RPG construction tools released by KADOKAWA Co.

Now let’s take a look at this video.

Demonstration Video (Youtube)

What do you think? Wasn’t it even more “RPG Maker” than you might have imagined? Some might even find it reminiscent of “Minecraft”. Most tasks can be accomplished with just a single click, copy and paste, or simple numeric input, eliminating the need for lengthy and complex coding or command typing. The button controls are also straightforward to understand.

Purely Domestic “PlantStream®”.

Seamlessly centralize plant layout design from plot plan studies to detailed piping design.

Before I go any further, I would like to add that PlantStream® is not an AI. It takes expert knowledge and know-how, formalizes it into rules, and processes data through algorithms. In other words, unlike AI deep learning, PlantStream® operation is based on human-defined rules.

Once you have arranged the pipe racks, pumps, vessels, etc. as you wish, automatic calculations begin at the touch of a button, and by the time you finish a sip of coffee, they are already connected. Each of them is precisely calculated, and MTO information such as pipe diameter, length, joints, etc. is instantly available.

Don’t you feel like you have a glimpse of the next generation of plant engineering work? I’m feeling a sense of relief regarding the uncertainties I’ve had for the future of this industry. These are no longer prototypes; they are now in operation one after another in the real world, and what’s even more remarkable is that they are made in Japan.

hat a joy for Japan, which is continuing to lose market share to the rest of the world in electric cars, drones, semiconductors, home appliances, cell phones, etc.

The Real Selling Point Is Not Speed but Accuracy

It’s certainly impressive to have the ability to automatically design 1,000 pipes in an instant, but the real standout feature is its precision. One would imagine that with 1,000 pipes, there might be a little bit of an adjustment, but the accuracy level is overwhelmingly higher than that of similar conventional products, and it has been highly rated by users.

Also, it is common to imagine that purely mechanical calculations may lack the reflection of an engineer’s design philosophy, including considerations such as maintenance space, usability, and safety. However, it should be noted that the algorithms employed in these calculations also draw extensively from the experiential knowledge of Chiyoda Corporation’s extensive experience, incorporating a human touch and common sense. This ensures users can confidently utilize them without any concerns about unnatural calculation results.

Evolution Continues, Even Electrical & Instrumentation Cables Can Now Be Designed Automatically.

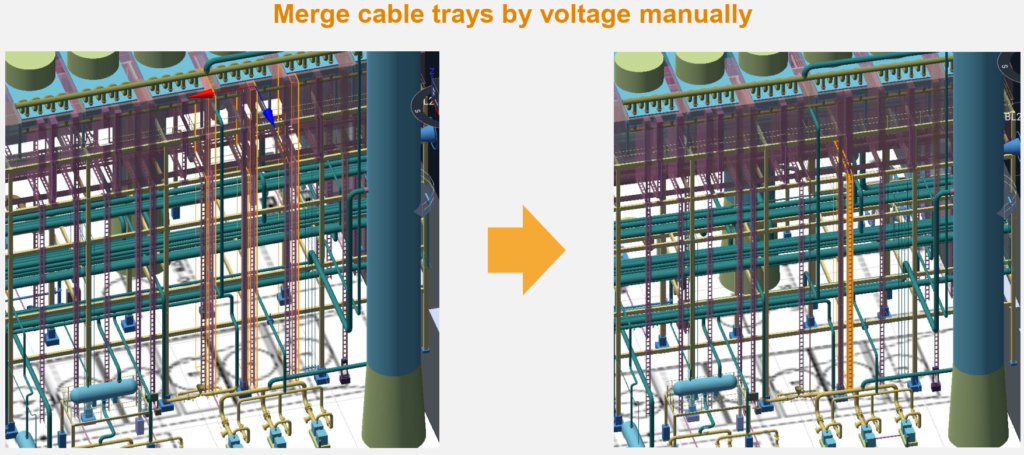

While the initial product was developed mainly for piping layout design, the latest version also supports electrical and instrumentation cable design.

It supports not only the routing of primary cables from electrical rooms and control centers plotted to rotating machines and distribution boards, but also secondary and control cables routing from LP and JB.

The system quickly lays out the auto cable route from the substation at the starting point to the equipment at the endpoint and precisely selects the cable tray width based on the cable specifications. Naturally, the system also sorts out low-voltage, high-voltage, and low-voltage power cables, and easily finds an available pipe rack route, without interfering with pipes, equipment, or steel frames and can be seen on the screen. As an Electrical engineer, I was truly amazed by this seamless process.

Thoughts Behind the Sophisticated UI

PlantStream® is not a tool that can be used exclusively by the joint venture partner, Chiyoda Corporation, but is also sold externally to plant engineering companies around the world, including competitors. The display is English-based, but even for non-English speakers, it wouldn’t be difficult to use since it has intuitive and easy-to-understand illustration icons and words that are commonly used in plant engineering.

According to the CEO, “Anyone can use it” is one of the key concepts.

If you have basic design knowledge, you can easily master basic PlantStream® operations within a few days, so it can be used without any resistance by young engineers or skilled engineers who are not used to operating software.

Of course, their Customer Success Team is ready to respond to your questions and concerns, so users can introduce the software with confidence.

It appears that Arent Co was originally engaged in game development, so their expertise in this area is being fully leveraged.

The user-friendly interface not only supports engineers’ design work but also helps solve challenges faced by the plant engineering industry.

What PlantStream® Solves

To review, what PlantStream® can solve is…

1. Design acceleration

2. Man-hour reduction

The system automatically routes up to 1,000 pipes per minute, while at the same time fulfilling all the basics of piping design, from the optimum arrangement of pipes on the pipe rack to the selection of top and bottom branch connection, with the high-quality of the routing.

Furthermore, by centralizing the workflow, it becomes much easier to share design concepts using 3D models and to accommodate design specification changes. This results in a highly streamlined coordination process with other departments, customers, and subcontractors. The implementation of PlantStream® can lead to an astonishing 80% reduction in man-hours for basic design tasks.

This is a very graphic story, but the negotiations and coordination among various design departments can be quite contentious, even within the same company. To put it bluntly, the more gentlemanly plant engineers tend to face more challenges. In truth, nobody really wants to engage in conflicts, as everyone knows it won’t lead to the highest quality plant. But unfortunately, we still get involved in it.

Undoubtedly, companies that have decided to implement PlantStream® will in turn find relief from the struggles and burdens of engineering tasks such as rework in designs, dual design efforts, deadline pressures, lack of engineers, and conflict.

The birth of PlantStream® can be rightfully described as a disruptive innovation that has the potential to reshape the weighty history of plant engineering.

This, of course, is a commendation.

They Can Change It Because They Are Ventures.

During my visit, I also had the opportunity to see the office, which had an atmosphere not usually found in plant engineering companies.

First of all, it looks simply fun.

Well, it’s a bit challenging to convey this adequately in just a few words, but everyone seemed to be energetic. Of course, I am sure there are many hardships. Nevertheless, the tone of their conversations was consistently upbeat, with members actively engaging in questions, discussions, and reports related to their assigned missions. It was just like a start-up company that I sometimes visit, with a sense of speed and a mysterious power to get things moving as quickly as possible. The staff is currently about 20 people.

They are flexible to remote work. There are no rules about clock-in and clock-out, and employees are allowed to manage their work. For this reason, each person is given discretion, and output is evaluated regardless of age or background.

As mentioned above, since PlantStream is a joint venture between Chiyoda Corporation and Arent Inc., it consists mainly of members from their respective companies. Although they are from different industries and corporate cultures, they respect each other and have succeeded in creating a single product through collaboration. This is because they work together for revolution and are all convinced that their product can achieve the challenges and goals of their customers.

Of course, I believe this is not an easy task, but I have the impression that they are beautifully integrated. To illustrate this, I could not tell which people were from which company.

In addition, the company is recently considering recruiting additional team members.

The number of inquiries from both domestic and overseas customers is rapidly increasing, and they require technical sales/consultant people who can convey the appeal of their products to overseas EPC contractors and plant owners.

Contact Us, etc.

Company name: PlantStream Inc.

Address: zip 104-0032

3-23-17 Takanawa, Minato-ku, Tokyo

Shinagawa Center Building 308

Phone number: +81-3-6222-8808

◎PlantStream® website: Click here

◎For product inquiries, please contact: Click here

Summary

Traditionally, plant engineers have demonstrated their value by doing their design work. However, plantstream was born as a result of serious DX efforts to eliminate business overload.

The knowledge and expertise previously handled by humans have been incorporated into this automated design program. In other words, it can be said that technology is passed down from person to software.

We felt that PlantStream was streaming in the best direction with the times.

(2023/8/18 Interviewed by Kazuki Takeuchi)